התפתחות מערכות הפצת חשמל תעשייתיות מודרניות

הסצנה של הפצת חשמל תעשייתית השתנתה דרמטית בעשור האחרון, עם תיבת התפלגות טכנולוגיה בחזית האבולוציה הזו. מתקני הייצור, מרכזי הנתונים והמתחמים התעשייתיים של ימינו דורשים פתרונות חלוקת חשמל מתוחכמים יותר ויותר המבטיחים אמינות, בטיחות ויעילות. מודרני תיבת התפלגות מערכות הפכו לאבן פינה של תשתיות חשמל, ומספקות יכולות ניהול חשמל חיוניות תוך עמידה בדרישות מחמירות של תעשיה.

בעודנו מתקרבים לשנת 2025, הסקטור התעשייתי ממשיך לאמץ עיצובים חדשניים של תיבות חלוק הכוללים טכנולוגיות חכמות, תכונות בטיחות משופרות ויעילות אנרגטית מוגברת. התקדמות זו משנה את הדרך בה עסקים ניגשים להפצת חשמל, מה שגורם לכך שהבנה של המוצרים העדכניים ביותר של יצרנים מובילים היא הכרחית למנהלי מתקנים ותכנון תעשייתי.

יצרני תיבות חלוק מובילים והחדשנות שלהם

יצרנים ברמה הגבוהה

בשוק הגבוה, בירכו מספר יצרנים לעצמם שם תקיף בזכות מחויבותם לאיכות ולחדשנות. חברות אלו משקיעות רבות במחקר ופיתוח, ומייצרות פתרונות של קופסאות חלוקה עם יכולות מתקדמות לניטור, הגנה משולבת מפני סופות, ועיצוב מודולרי להרחבה קלה.

קווי המוצרים שלהם כוללים בדרך כלל מערכות קופסת חלוקה חכמות עם יכולת ניטור מרחוק, המאפשרות למנהלי תשתיות לעקוב אחר דפוסי צריכה ולהזהיר על בעיות פוטנציאליות לפני שהן הופכות לקритיות. היצרנים הללו מדגישים גם את הנושא של עמידות סביבתית, ושואבים חומרים ידידותיים לסביבה ומעצבים מוצרים שממקסמים את חלוקת האנרגיה כדי לצמצם בזבוז.

פתרונות טווח תיכוני עם ערך יוצא דופן

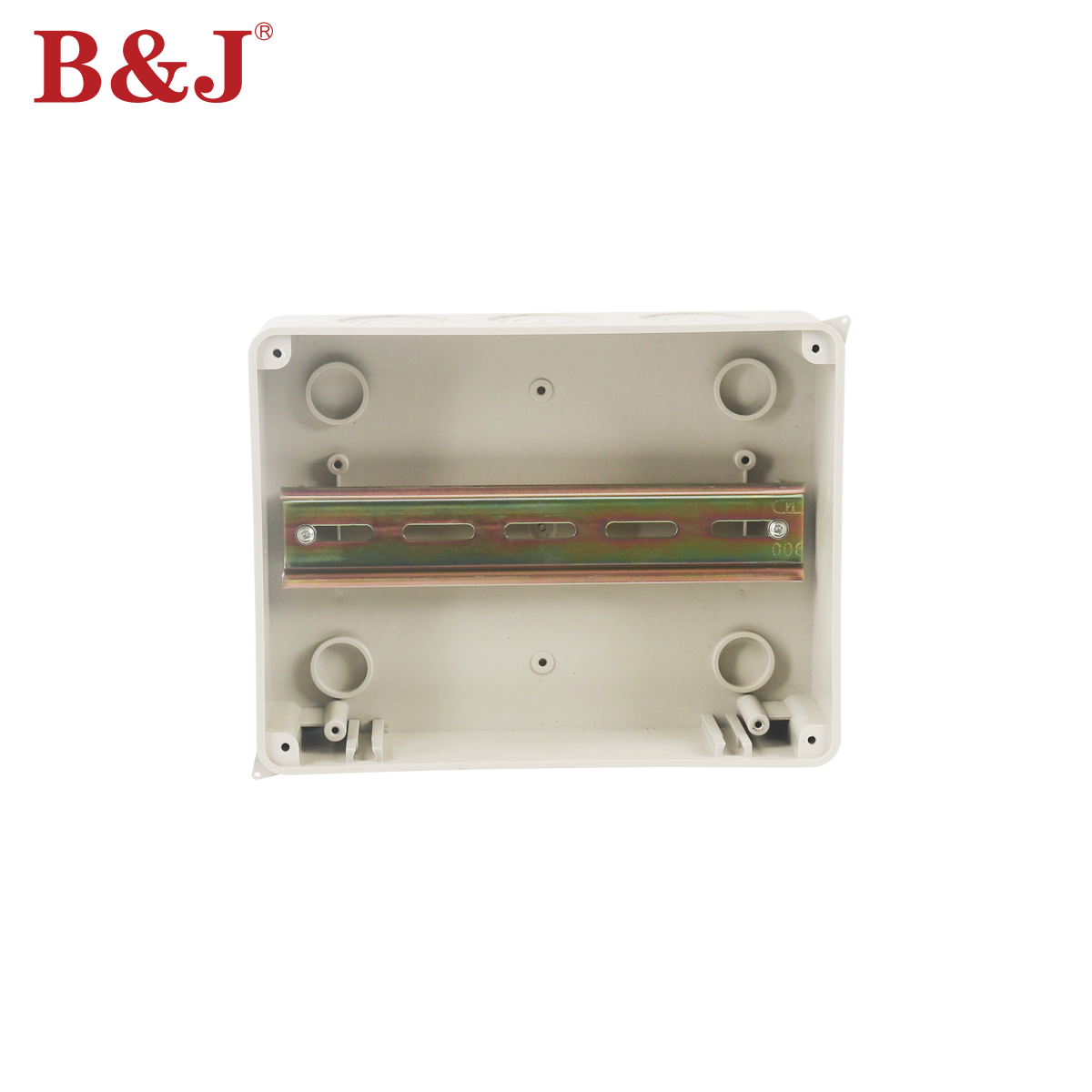

קטע השוק הבינוני מציע איזון מצוין בין תכונות לנגישות. יצרנים אלו מתמקדים בייצור של מוצרי קופסאות פיזור אמינות הכוללות תכונות בטיחות חיוניות, תוך שמירה על תמחור תחרותי. הפתרונות שלהם כוללים לעתים קרובות כיסויים עמידים למזג אוויר, מערכות סימון ברורות ורכיבים סטנדרטיים המפשטים תחזוקה ותיקונים.

רבות מהחברות פיתחו קווי קופסאות פיזור מיוחדים לשימושים תעשייתיים מסוימים, כגון מתקני עיבוד מזון או מפעלי כימיקלים, ובכך מבטיחים התאמה להנחיות התעשיות הספציפיות תוך עמידה בדרישות הפעילות הייחודיות.

מפרטים טכניים ותכונות שחשוב לקחת בחשבון

אישור ובריאות

בעת הערכת אפשרויות של קופסאות חלוקה, יש להתחשב באישורי בטיחות כגורם עיקרי. יצרנים מובילים מבטיחים שמוצריהם עומדים או עולים על תקני הבטיחות הבינלאומיים, כולל אישורי IEC, UL ו-CE. אישורים אלו מאששים את תכונות הבטיחות של המוצר, כגון הגנה מפני קצר, הגנה מפני עומס והגדרות בידוד מתאימות.

יתרה מכך, מערכות קופסת חלוקה מודרניות צריכות לעמוד בדרישות תעסוקתיות מסוימות, כגון דירוגי IP להגנה מפני מים ואבק, ותקני NEMA להגנת הסביבה. אישורים אלו מספקים ודאות שהציוד יפעל באופן מהימן בסביבות תעשייתיות קשות.

יכולות אינטגרציה חכמות

שילוב של טכנולוגיה חכמה הפך להיות חשוב יותר ויותר בעיצוב תיבות פיזור. מערכות מתקדמות מציעות כעת תכונות כגון ניטור איכות חשמל, ניתוח צריכה ואזהרות לתחזוקה חיזויית. יכולות אלו מאפשרות אסטרטגיות תחזוקה פרואקטיביות ועוזרות באופטימיזציה של צריכת האנרגיה במתקנים תעשייתיים.

פתרונות תיבות פיזור מודרניות כוללות לעיתים קרובות פרוטוקולי תקשורת המאפשרים שילוב חלק עם מערכות ניהול בניין ורשתות אוטומציה תעשייתית. החיבוריות הזו מאפשרת ניטור ובקרה בזמן אמת, ותומכת בטרנד הגובר ליישום התעשייה 4.0.

הדברים שצריך לקחת בחשבון בהתקנה והתחזוקה

דרישות לתקנת מקצועית

התקנת נכונה של מערכות תיבות פיזור תעשייתיות היא קריטית לביצועים אופטימליים ולבטיחות. יצרנים מובילים מספקים הנחיות מפורטות להתקנה וчасто מציעים תוכניות של מתקינים מאושרים כדי להבטיח שהמוצרים יותקנו נכון. זה כולל مواصفות להרכבה, ניהול כבלים והיבטים סביבתיים.

דרישות ההתקנה עשויות להשתנות בהתאם ליישום הספציפי ולתקני החשמל המקומיים. חשוב לעבוד עם קבלני חשמל מוסמכים שמבינים את הדרישות האלה ויודעים להבטיח עמידה בכל התקנות הרלוונטיות.

פרוטוקולי תחזוקה ומمارسות מומלצות

תחזוקה שגרתית היא עניין חיוני להבטחת אורך החיים והאמינות של מערכות תיבות הפצה. יצרנים מובילים ממליצים על בדיקות מתוכננות וاجendas לתחזוקה, כולל סקרי הדמיה תרמית, בדיקות חיבורים ודיאגרמת בידוד. נהלי תחזוקה אלו עוזרים למנוע כשלים בציוד ומאריכים את חיי השירות של מערכת הפצה.

עיצובים מודרניים של תיבות הפצה לעתים קרובות כוללים תכונות המקלות על תחזוקה קלה יותר, כגון דפנות גישה ללא כלים, רכיבים מודולריים ומערכות זיהוי ברורות. תכונות אלו מקטינות את זמן התחזוקה ומפחיתות למינימום את הסיכון לשגיאות במהלך הליכי שירות.

ניתוח עלויות ותשואה על ההשקעה

שקול השקעה ראשונית

בעוד עלות ההתחלה של מערכת תיבת הפצה משתנה במידה רבה בהתאם ליכולת ולתכונות, חשוב לקחת בחשבון את העלות הכוללת של בעלות. יצרנים מובילים מוצאים לעצמם הצדקה לעלות התחלה גבוהה יותר באמצעות איכות בנייה גבוהה יותר, מחזור חיים ארוך יותר ותכונות מתקדמות שתרמו ליעילות התפעול.

בעת הערכת העלויות, יש לקחת בחשבון גורמים כגון דרישות התקנה, כיסוי האחריות ותמיכת היצרן יחד עם מחיר הקנייה. רבים מהיצרנים מציעים אפשרויות מימון ויכולים לספק ניתוחי תשואה מפורטים בהתבסס על דרישות יישום ספציפיות.

ערך ארוך טווח ויעילות אנרגטית

תכונות של יעילות אנרגטית במערכות מתקדמות של תיבות הפצה יכולות להשפיע משמעותית על עלויות תפעול ארוכות-טווח. יכולות מתקדמות של ניטור חשמל ואופטימיזציה של הפצת חשמל יכולות להוביל לחיסכון משמעותי באנרגיה לאורך זמן. בנוסף, אמינות ועמידות של מערכות הפצה איכותיות מפחיתות את עלויות התיקון וממזערות עיכובים יקרים.

יצרנים يولיכים יותר ויותר לכיוון עיצוב פתרונות של תיבות הפצה שתומכים ביוזמות קיימות-בידוק תוך כדי שמייצרים ערך ארוך-טווח על ידי צמצום צריכה של אנרגיה ודרישות תחזוקה.

שאלות נפוצות

מהו אורך החיים הרגיל של תיבת הפצה תעשייתית?

לתיבת הפצה תעשייתית באיכות גבוהה יש בדרך כלל מחזור חיים של 15–20 שנה כאשר מתבצעת תחזוקה נכונה. עם זאת, זה יכול להשתנות בהתאם לתנאי סביבה, דפוסי שימוש ונהלי תחזוקה. בדיקות שגרתיות ותחזוקה מניעה יכולות להאריך בצורה משמעותית את חיי הפעולה של המערכת.

באיזו תדירות יש לבדוק את ארון החלוקה?

יש לבצע בדיקות מקצועיות לפחות פעם אחת בשנה, עם המלצות לביצוע בדיקות תכופות יותר עבור התקנות קריטיות או בסביבות קשות. בדיקות ויזואליות חודשיות על ידי צוות מוסמך של המתקן יכולות לסייע בזיהוי בעיות פוטנציאליות בשלב מוקדם. נסיעות הדמיה תרמית מומלצות בדרך כלל כל שישה חודשים כדי לגלות נקודות חמות או בעיות חיבור.

אילו גורמים צריכים להשפיע על בחירת קופסת חלוקה?

גורמים עיקריים כוללים את הקיבולת החשמלית הנדרשת, תנאי הסביבה, דרישות בטיחות, נגישות לתצורה ולתחזוקה, וצורך בהתפשטות עתידית. יש לקחת בחשבון גם את מוניטין היצרן, תנאי האחריות, זמינות תמיכה מקומית, והامتثال לתקנות ספציפיות של הענף. עלות הבעלות הכוללת, הכוללת יעילות אנרגטית ודרישות תחזוקה, צריכה גם כן להערכות בזהירות.