Understanding Modern Electrical Distribution Systems

The complexity of modern electrical systems requires careful consideration of how power is distributed throughout buildings. At the heart of these systems lies the critical decision between using a distribution box and an electrical panel. While both components play essential roles in power management, their functions and applications differ significantly. Let's explore the intricate details of these vital electrical components to help you make informed decisions for your electrical infrastructure needs.

Core Components and Basic Functions

Distribution Box Fundamentals

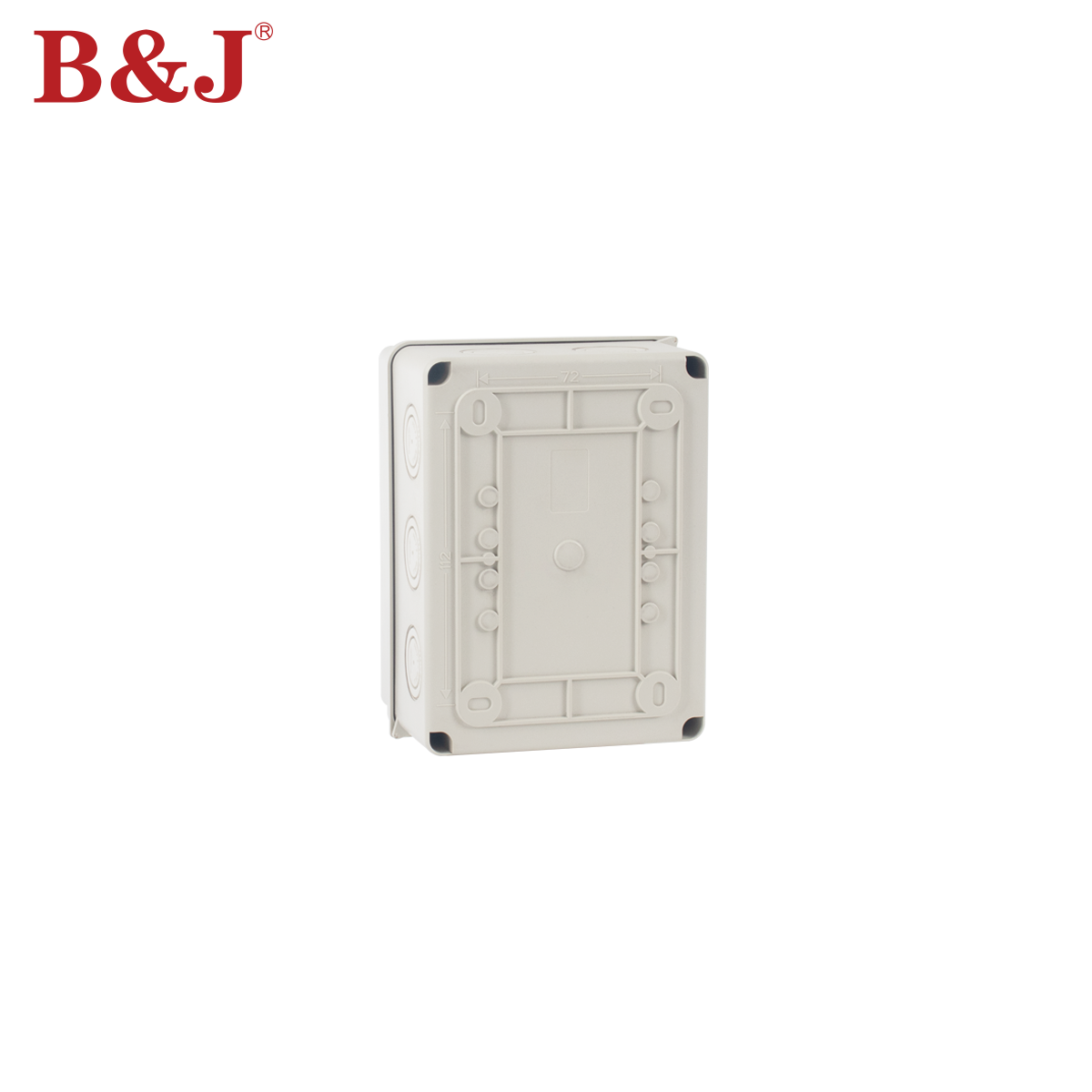

A distribution box serves as a crucial intermediary in the electrical system, managing the flow of electricity from the main power source to various circuits. This component typically houses circuit breakers, fuses, and terminals that facilitate the organized distribution of electrical power. The distribution box acts as a central hub, allowing for systematic power allocation while maintaining safety protocols and enabling easy access for maintenance.

Modern distribution box designs incorporate advanced features such as surge protection, intelligent monitoring capabilities, and modular configurations. These innovations enhance both safety and flexibility, making it easier to modify or expand the system as needed. The compact nature of a distribution box makes it particularly suitable for residential and small commercial applications where space efficiency is paramount.

Electrical Panel Characteristics

Electrical panels, often referred to as breaker boxes or load centers, represent the primary control point for a building's electrical system. These panels contain the main circuit breaker and multiple branch circuit breakers, serving as the central distribution point for incoming electrical service. Unlike a distribution box, electrical panels typically handle higher amperage and voltage requirements, making them essential for larger installations.

The robust construction of electrical panels accommodates more substantial power demands and provides comprehensive circuit protection. They often include features like ground fault circuit interrupters (GFCIs), arc fault circuit interrupters (AFCIs), and sophisticated monitoring systems that ensure optimal performance and safety compliance.

Technical Specifications and Capabilities

Load Handling and Capacity

When comparing a distribution box to an electrical panel, load handling capacity emerges as a crucial differentiator. A typical distribution box manages smaller electrical loads, usually ranging from 60 to 200 amperes, making it suitable for subdividing power from a main panel to specific areas or equipment. This controlled distribution helps maintain system stability and prevents overloading of individual circuits.

The design of distribution boxes emphasizes efficient power management through carefully planned circuit arrangements. This organization allows for better load balancing and reduces the risk of circuit overload, particularly in applications where multiple devices or appliances share power resources.

Safety Features and Protection Mechanisms

Modern distribution box systems incorporate multiple layers of safety features to protect both equipment and users. These include thermal protection, short circuit protection, and overcurrent protection mechanisms. The compact design allows for quick isolation of faulty circuits while maintaining power to unaffected areas, minimizing downtime and potential hazards.

Advanced distribution box models now feature smart monitoring capabilities that can detect potential issues before they become critical. This predictive maintenance approach helps prevent electrical failures and extends the lifespan of connected equipment. The integration of these safety features makes the distribution box an essential component in maintaining electrical system integrity.

Installation and Maintenance Considerations

Space Requirements and Positioning

The installation of a distribution box requires careful consideration of space and accessibility. These units typically occupy less wall space than full electrical panels, making them ideal for areas with spatial constraints. Proper positioning ensures easy access for maintenance while maintaining compliance with local electrical codes and safety standards.

Strategic placement of distribution boxes can optimize power distribution efficiency and reduce voltage drops across longer distances. This careful planning contributes to better overall system performance and can result in significant energy savings over time.

Maintenance Protocols and Upgrades

Regular maintenance of distribution box systems is essential for ensuring continued reliable operation. This includes periodic inspection of connections, testing of protection devices, and cleaning of components to prevent dust accumulation. The modular nature of modern distribution boxes facilitates easier replacement of worn components and system upgrades when needed.

Implementing a structured maintenance schedule helps identify potential issues early and extends the service life of the distribution system. Professional electricians can perform thorough assessments and necessary updates while ensuring compliance with evolving safety standards and regulations.

Cost Analysis and Long-term Value

Initial Investment Considerations

When evaluating the cost of a distribution box versus an electrical panel, several factors come into play. The initial investment for a distribution box is typically lower, reflecting its more focused role in the electrical system. However, the total cost should consider installation requirements, additional components, and potential future expansion needs.

Quality distribution boxes offer excellent value through their durability, reliability, and efficient power management capabilities. The investment often pays off through reduced maintenance costs and improved energy efficiency over the system's lifetime.

Operational Cost Impact

The operational costs associated with distribution box systems tend to be lower due to their simplified design and fewer components requiring maintenance. Energy efficiency features in modern distribution boxes can contribute to reduced power consumption and lower utility bills. The ability to isolate and manage specific circuits effectively also helps optimize energy usage patterns.

Long-term cost benefits include reduced downtime during maintenance, lower replacement part expenses, and improved energy management capabilities. These factors contribute to a favorable total cost of ownership when compared to more complex electrical distribution solutions.

Frequently Asked Questions

What are the main advantages of using a distribution box in residential settings?

Distribution boxes offer several benefits for residential applications, including space efficiency, simplified circuit management, and cost-effective power distribution. They provide excellent protection for branch circuits while maintaining easy access for maintenance and modifications. The compact design makes them particularly suitable for homes where space is at a premium.

How often should a distribution box be inspected and maintained?

Professional inspection of a distribution box should be conducted annually, with more frequent checks in industrial or high-usage environments. Regular maintenance includes testing circuit breakers, checking connections for tightness, and cleaning any dust or debris. Visual inspections should be performed monthly to identify any signs of wear or damage.

Can a distribution box be upgraded to accommodate increased power demands?

Most modern distribution boxes are designed with some capacity for expansion. However, any significant increases in power demand should be carefully evaluated by a qualified electrician. Upgrades might involve replacing existing components with higher-rated alternatives or installing additional distribution boxes to handle the increased load safely.