Essential Care Guidelines for Electrical Distribution Systems

The reliability of any electrical system heavily depends on the proper maintenance of its distribution box. As a central component that manages power flow throughout a facility, a well-maintained distribution box ensures safety, efficiency, and uninterrupted operations. Understanding how to properly care for these vital electrical components can significantly extend their lifespan and prevent costly breakdowns.

Modern industrial and commercial facilities rely extensively on their electrical distribution systems. At the heart of these systems, the distribution box serves as a crucial junction point, directing electrical current to various circuits while providing essential protection against overloads and short circuits. Regular maintenance not only preserves the functionality of your distribution box but also helps identify potential issues before they escalate into major problems.

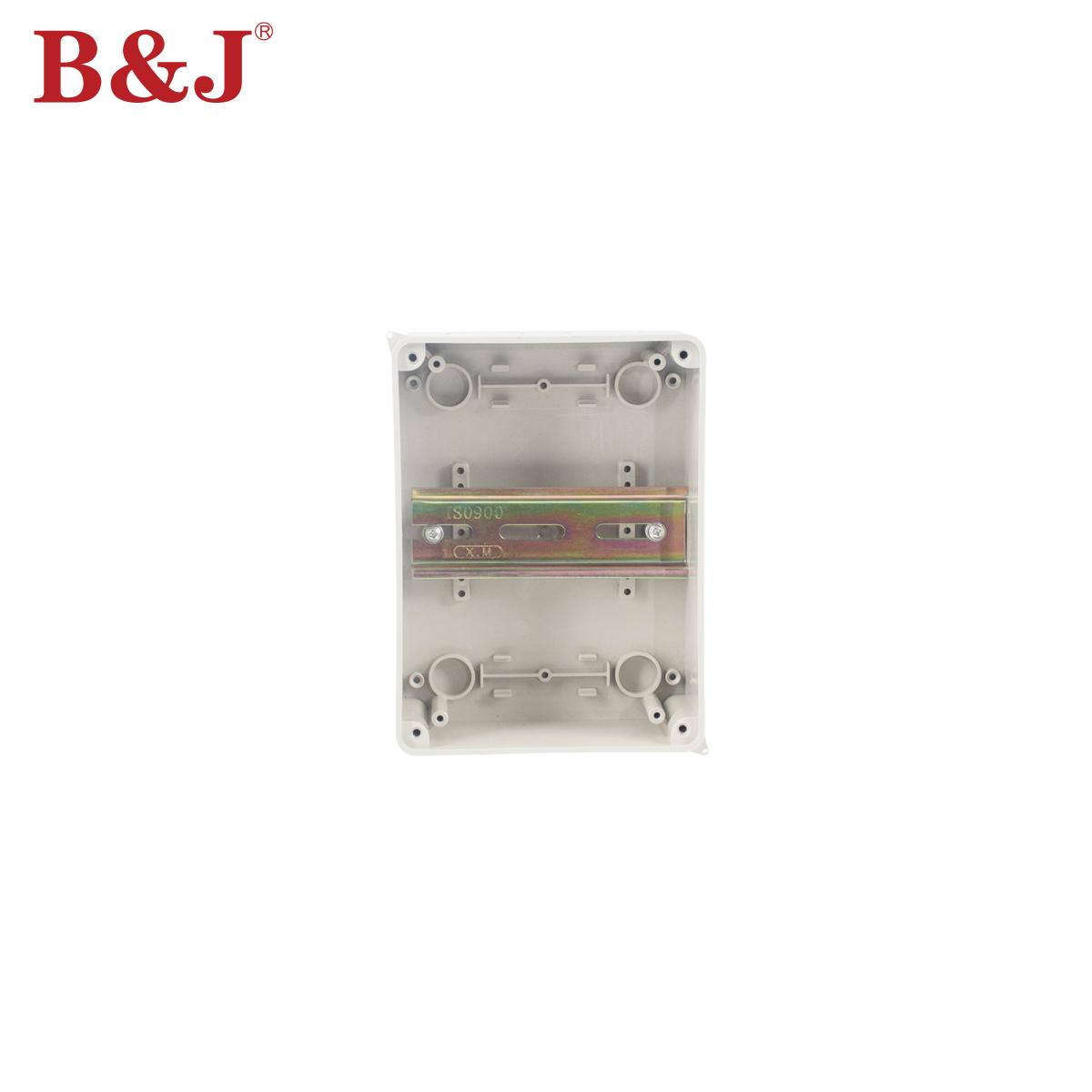

Understanding Your Distribution Box Components

Main Circuit Breakers and Switches

The primary components of a distribution box include the main circuit breaker, which serves as the first line of defense against electrical overloads. These breakers require regular inspection to ensure smooth operation of their mechanical parts. Look for signs of wear, heat damage, or corrosion on the breaker contacts. The main switch mechanism should operate smoothly without sticking or requiring excessive force.

Regular testing of circuit breakers helps verify their trip mechanisms are functioning correctly. This testing should be performed by qualified personnel who can safely simulate overload conditions and verify proper breaker response. Documentation of these tests should be maintained as part of your maintenance records.

Bus Bars and Internal Connections

Bus bars within the distribution box carry substantial electrical loads and must maintain proper connection integrity. These components should be inspected for signs of oxidation, discoloration, or loose connections. Any evidence of heat damage, such as melted insulation or scorched materials, requires immediate attention.

Connection points between bus bars and circuit breakers are particularly critical. These joints can loosen over time due to thermal cycling and vibration. Regular torque checking of these connections helps prevent hot spots and potential failure points within the distribution box.

Preventive Maintenance Schedules

Monthly Visual Inspections

Implementing a regular visual inspection routine is crucial for maintaining your distribution box. Monthly checks should include examining the external condition of the enclosure, verifying proper ventilation, and ensuring all labels and warnings are legible. Look for signs of moisture intrusion, pest infestation, or physical damage to the cabinet.

During these inspections, verify that the distribution box area remains clear of obstacles and maintains proper clearance for ventilation and access. Document any unusual sounds, smells, or visible changes that might indicate developing problems.

Quarterly Technical Assessments

More detailed technical assessments should be performed quarterly by qualified electricians. These evaluations include thermal imaging to identify hot spots, measurement of load balance across phases, and verification of proper grounding connections. The distribution box should be carefully cleaned of dust and debris, with particular attention to ventilation openings and cooling systems.

Current readings for each circuit should be recorded and compared to previous measurements to identify any developing trends. Unusual patterns in power consumption might indicate problems with connected equipment or degrading connections within the distribution box itself.

Environmental Control Measures

Temperature Management Solutions

Maintaining proper operating temperature is critical for the longevity of your distribution box. Excessive heat can accelerate the degradation of insulation materials and increase electrical resistance at connection points. Install temperature monitoring devices and ensure proper ventilation to maintain optimal operating conditions.

Consider implementing additional cooling solutions in high-temperature environments. This might include forced ventilation, air conditioning, or specialized enclosure designs that promote better heat dissipation. Regular monitoring of ambient and internal temperatures helps identify potential cooling system failures before they impact equipment operation.

Moisture and Dust Protection

Environmental contaminants pose significant risks to distribution box reliability. Implement appropriate sealing measures to prevent dust and moisture infiltration. Regular inspection of gaskets, seals, and cable entry points helps maintain the integrity of these protective barriers.

In particularly challenging environments, consider installing dehumidifiers or implementing positive pressure systems to prevent moisture accumulation. Regular cleaning of air filters and ventilation systems helps maintain proper airflow while preventing dust buildup inside the distribution box.

Emergency Response and Troubleshooting

Common Issues and Solutions

Develop a comprehensive troubleshooting guide for common distribution box issues. Train maintenance personnel to recognize warning signs such as unusual noises, odors, or visual indicators of potential problems. Quick response to these early warning signs can prevent more serious failures.

Maintain an inventory of critical spare parts to minimize downtime during emergencies. This should include commonly needed items such as fuses, circuit breakers, and control components specific to your distribution box configuration.

Documentation and Reporting

Maintain detailed records of all maintenance activities, repairs, and modifications to your distribution box. This documentation helps track equipment history, identify recurring issues, and plan preventive maintenance activities more effectively.

Implement a clear reporting system for maintenance personnel to communicate issues and concerns. Regular review of these reports helps identify patterns and potential areas for improvement in maintenance procedures.

Frequently Asked Questions

How often should a distribution box be professionally inspected?

Professional inspections should be conducted at least annually, with more frequent inspections recommended for critical installations or harsh environments. These inspections should include thermal imaging, load testing, and detailed component evaluation by qualified electricians.

What are the signs that a distribution box needs immediate attention?

Key warning signs include unusual noises (buzzing or humming), burning smells, visible damage to components, frequent circuit breaker trips, or warm spots on the enclosure. Any of these symptoms warrant immediate professional inspection.

Can distribution boxes be upgraded to improve reliability?

Yes, distribution boxes can be upgraded with modern components such as smart monitoring systems, improved circuit breakers, or enhanced ventilation systems. These upgrades should be carefully planned and implemented by qualified professionals to ensure compatibility and maintain safety standards.