Choosing the right electrical enclosure for your industrial application is a critical decision that impacts safety, durability, and operational efficiency. Whether you're designing control panels, housing sensitive electronics, or protecting electrical components from harsh environments, the material selection between metal and plastic enclosures significantly influences performance outcomes. Each material offers distinct advantages and limitations that must be carefully evaluated based on specific application requirements, environmental conditions, and budget constraints. Understanding these differences ensures optimal protection for your electrical systems while maximizing return on investment.

Material Properties and Structural Characteristics

Metal Enclosure Construction Features

Metal electrical enclosures, primarily manufactured from steel, aluminum, or stainless steel, provide exceptional structural integrity and mechanical protection. Steel enclosures offer superior strength-to-weight ratios, making them ideal for heavy-duty industrial applications where robust protection is paramount. The inherent rigidity of metal construction ensures dimensional stability under mechanical stress, thermal cycling, and vibration conditions commonly encountered in manufacturing environments.

Aluminum enclosures combine lightweight properties with excellent corrosion resistance, particularly in marine or coastal applications where salt exposure is a concern. The natural oxide layer formation on aluminum surfaces provides additional protection against environmental degradation. Stainless steel variants offer the highest level of corrosion resistance but at increased material costs, making them suitable for pharmaceutical, food processing, and chemical industry applications.

Plastic Enclosure Material Advantages

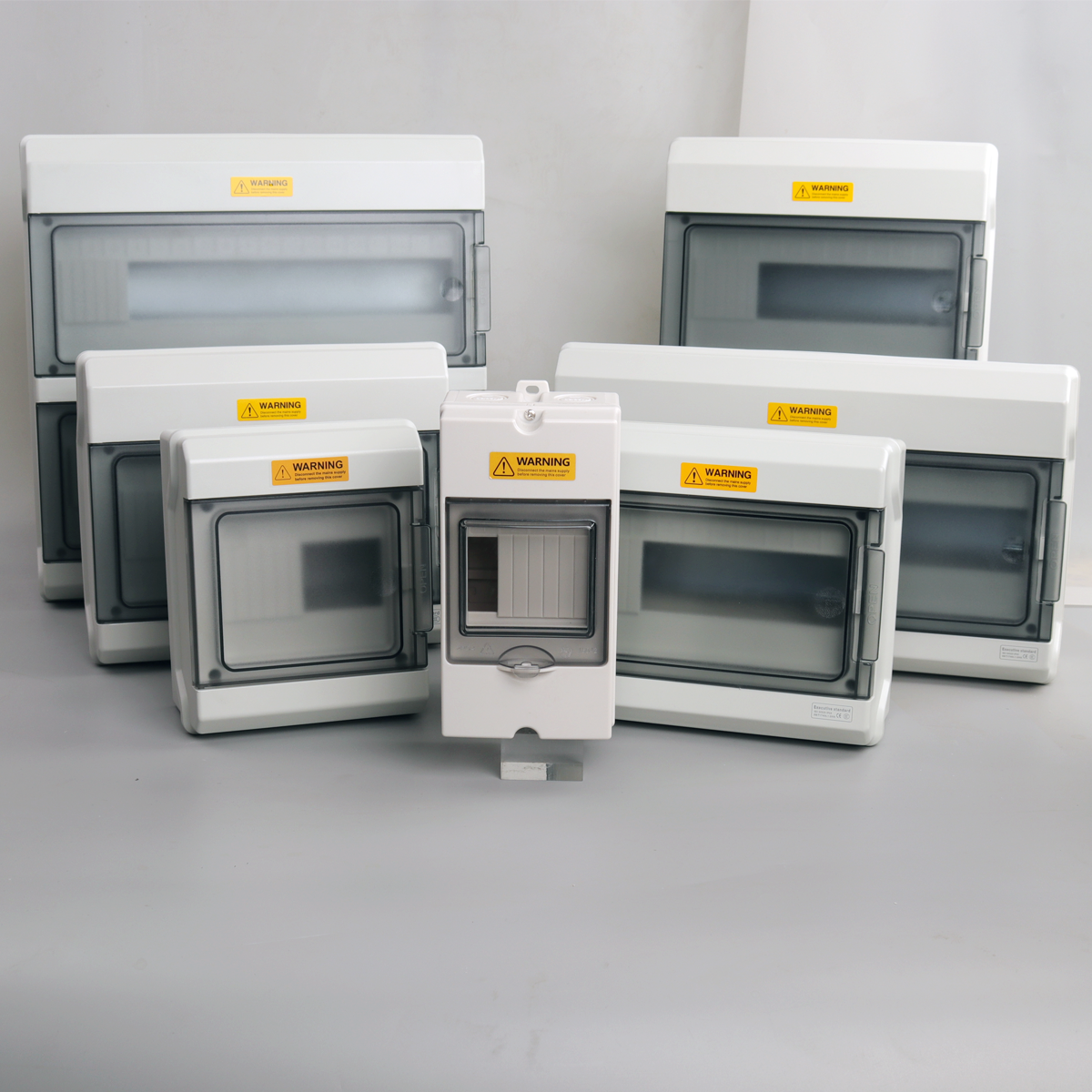

Modern plastic enclosures utilize advanced engineering polymers such as polycarbonate, ABS, or fiberglass-reinforced plastics that deliver impressive performance characteristics. These materials offer inherent corrosion immunity, eliminating concerns about rust, oxidation, or galvanic corrosion that can affect metal counterparts. The chemical inertness of quality plastics makes them suitable for environments with aggressive chemicals, acids, or alkaline substances.

Plastic enclosures provide excellent electrical insulation properties, reducing the risk of electrical faults or grounding issues. This characteristic is particularly valuable in applications where the electrical enclosure must maintain electrical isolation from surrounding conductive materials. Additionally, plastic materials can be formulated with flame-retardant additives to meet specific fire safety requirements without compromising structural integrity.

Environmental Performance and Durability

Weather Resistance and Outdoor Applications

Metal enclosures demonstrate exceptional performance in extreme weather conditions, withstanding temperature fluctuations, UV exposure, and physical impact better than most plastic alternatives. Properly coated metal surfaces resist weathering effects and maintain protective properties over extended service periods. The thermal mass of metal construction provides natural temperature buffering, helping to moderate internal temperature variations that could affect sensitive electronic components.

However, metal enclosures require appropriate surface treatments such as powder coating, galvanizing, or anodizing to prevent corrosion in outdoor environments. These protective coatings may require periodic maintenance or renewal depending on exposure conditions. Salt spray, industrial pollutants, and moisture can compromise coating integrity over time, potentially leading to substrate corrosion if not properly maintained.

Chemical and Moisture Resistance

Plastic enclosures excel in chemically aggressive environments where metal alternatives would suffer rapid degradation. The non-porous nature of quality plastic materials prevents moisture absorption and chemical penetration, maintaining protective barrier properties throughout their service life. This resistance extends to cleaning agents, solvents, and process chemicals commonly encountered in industrial facilities.

Modern plastic formulations incorporate UV stabilizers and weathering agents that significantly extend outdoor service life. These additives prevent polymer degradation, color fading, and embrittlement that historically limited plastic enclosure applications. Advanced engineering plastics can now provide decades of reliable service in outdoor installations without significant property degradation.

Thermal Management and Heat Dissipation

Metal Thermal Conductivity Benefits

The superior thermal conductivity of metal enclosures provides significant advantages for applications generating substantial heat loads. Metal construction facilitates efficient heat transfer from internal components to the exterior surface, where natural convection or forced cooling can effectively remove thermal energy. This characteristic is crucial for high-power electronic systems, motor control panels, and frequency drives that generate considerable heat during operation.

Aluminum enclosures offer particularly excellent thermal management properties, with thermal conductivity approximately 200 times greater than typical plastic materials. This dramatic difference in heat transfer capability can significantly impact component operating temperatures, reliability, and service life. Metal enclosures can often eliminate the need for active cooling systems, reducing overall system complexity and energy consumption.

Plastic Thermal Insulation Properties

While plastic materials generally exhibit poor thermal conductivity, this characteristic can be advantageous in specific applications. The thermal insulation properties of plastic enclosures help maintain stable internal temperatures in environments with extreme ambient temperature variations. This stability can benefit temperature-sensitive instrumentation or control systems requiring consistent operating conditions.

For low-power electronic applications where heat generation is minimal, plastic enclosures provide adequate thermal management while offering other performance benefits. The thermal insulation effect can actually improve energy efficiency in heated enclosures by reducing heat loss to the surrounding environment. However, high-power applications typically require metal construction or specialized thermal management solutions to prevent component overheating.

Cost Considerations and Economic Factors

Initial Investment and Material Costs

Plastic enclosures generally offer lower initial purchase costs compared to metal alternatives of similar size and rating. The material costs, manufacturing processes, and tooling requirements for plastic production typically result in more economical solutions for standard applications. This cost advantage becomes more pronounced for large-volume requirements where economies of scale can be realized.

However, cost comparisons must consider the complete lifecycle economics rather than just initial purchase price. Factors such as installation complexity, maintenance requirements, and expected service life significantly impact total cost of ownership. Metal enclosures may justify higher initial costs through extended service life, reduced maintenance needs, or superior protection capabilities that prevent costly equipment failures.

Maintenance and Lifecycle Economics

Metal enclosures often require periodic maintenance such as coating touch-ups, gasket replacement, or corrosion treatment depending on environmental exposure. These maintenance activities represent ongoing operational costs that should be factored into economic evaluations. However, properly maintained metal enclosures can provide service lives exceeding 20-30 years in appropriate applications.

Plastic enclosures typically require minimal maintenance once installed, with no coating or corrosion concerns. The inherent material properties remain stable throughout the service life without requiring protective treatments. This maintenance-free operation can provide significant cost savings in applications where access is difficult or maintenance personnel availability is limited. However, plastic enclosures may have shorter overall service lives in demanding applications, potentially requiring more frequent replacement.

Installation and Mounting Considerations

Mechanical Mounting and Support Requirements

Metal enclosures provide excellent mounting stability and can support substantial internal component weights without structural deformation. The rigid construction allows for secure mounting of heavy transformers, contactors, and other substantial electrical components without compromising enclosure integrity. Standard mounting hardware and techniques work effectively with metal construction, simplifying installation procedures.

The structural strength of metal enclosures enables various mounting configurations including wall mounting, pole mounting, or free-standing installations. Multiple mounting points can distribute loads effectively across the enclosure structure, ensuring long-term mounting reliability. This versatility makes metal enclosures suitable for applications requiring flexible installation options or frequent reconfiguration.

Electrical Grounding and Bonding

Metal enclosures provide inherent electrical continuity that facilitates effective system grounding and electromagnetic compatibility. The conductive enclosure shell can serve as part of the electrical system grounding path, simplifying installation requirements and improving electrical safety. Proper bonding techniques ensure reliable fault current paths and equipment protection.

Plastic enclosures require additional considerations for electrical grounding since the enclosure material provides no conductive path. Separate grounding conductors must be installed to ensure proper system grounding and safety. This requirement may increase installation complexity and costs but provides electrical isolation benefits in specific applications where ground loops or electrical noise could be problematic.

FAQ

Which electrical enclosure material is better for outdoor applications?

Metal enclosures generally perform better in outdoor applications due to their superior structural strength, temperature stability, and resistance to physical damage. However, they require proper surface treatments to prevent corrosion. High-quality plastic enclosures with UV stabilizers can also provide excellent outdoor performance with lower maintenance requirements, particularly in chemically aggressive environments where metal corrosion is a concern.

How do thermal management requirements affect material selection?

Applications with significant heat generation typically require metal enclosures due to their superior thermal conductivity. Metal construction facilitates efficient heat dissipation, preventing component overheating and extending equipment life. Plastic enclosures are suitable for low-power applications but may require active cooling or thermal management solutions for higher heat loads.

What factors should influence cost-based material decisions?

Consider total lifecycle costs rather than just initial purchase price. Plastic enclosures offer lower upfront costs and minimal maintenance requirements, while metal enclosures may provide longer service life and better protection for critical applications. Evaluate installation complexity, maintenance needs, expected service life, and replacement costs to determine the most economical solution for your specific application.

Are there specific safety considerations for each material type?

Both materials can provide excellent safety performance when properly selected and installed. Metal enclosures offer superior fire resistance and structural protection but require proper grounding for electrical safety. Plastic enclosures provide electrical isolation benefits and inherent corrosion resistance but may have lower fire resistance unless specifically formulated with flame-retardant additives. Choose based on specific safety requirements and environmental conditions.